DAIKIN IPM motor

Double torque for high energy savings

A Daikin IPM motor is superior because it uses a double rotational force produced by two types of torque: neodymium (magnet torque) and Daikin’s original reluctance torque. The combination of these two forces increases power while using less electricity to deliver energy savings.

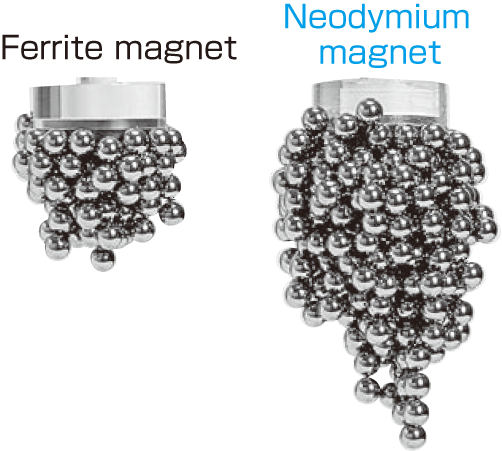

Powerful neodymium magnets are what gives Daikin IPM motors their energy-saving effect.

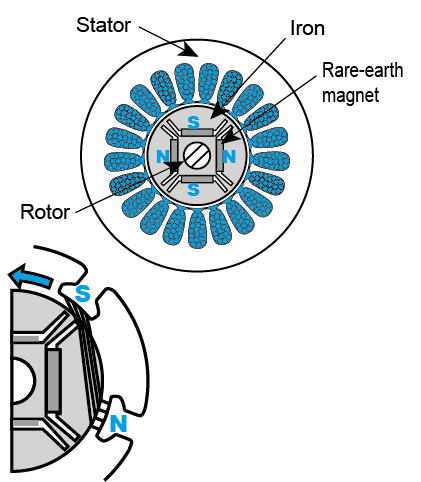

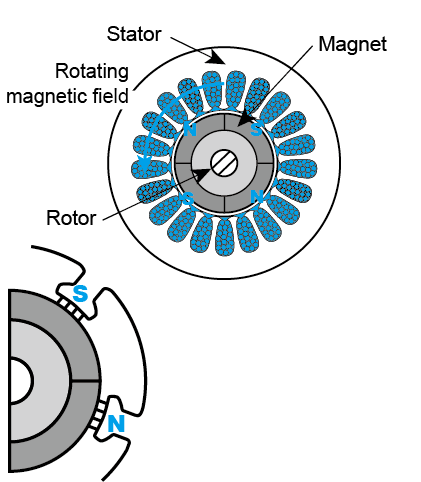

The fundamentals of IPM motors

A rare-earth permanent magnet deeply positioned in the rotor generates magnet torque (attraction/repulsion between coil and permanent magnet) and reluctance torque (coil attracts iron). This electromagnetic structure attains high torque for the highest possible efficiency.

Structure of a conventional AC servo motor

Surface permanent magnet (SPM) motor

The lengths of the magnetic field lines at the south and north poles are equivalent, which means there’s no rotational force or reluctance force generated.

Structure of a Daikin IPM motor

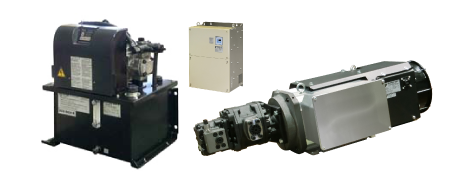

IPM motor drive system

The magnetic field lines at the south pole side are longer than the north side. Similar to how a stretched rubber band contracts, the magnetic field lines at the south pole will try to shorten. As a result, a rotational force will occur due to the reluctance torque moving in a counterclockwise direction (see the arrow in the illustration).

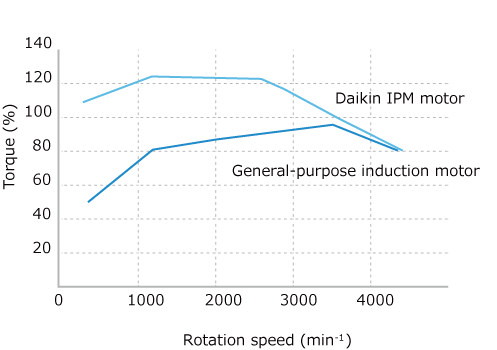

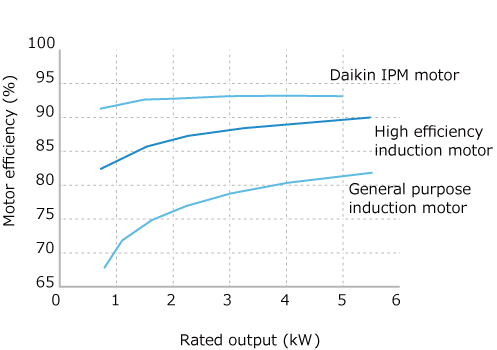

Comparing the results

Motor efficiency

The efficiency of a Daikin IPM is much higher than an induction motor, especially at low motor rotation speed.

High torque at a low-speed range

Daikin IPM motors produce high torque at a low speed. Generally, an inverter type may have limited torque when set at a low-speed range, but Daikin IPM motors can work around this technicality.