Oil cooling unit AKC9 Features

Features of AKC9 series are explained.

Oil cooling unit AKC9 SERIES Circulating typeRoHS-compliant Features

- Inline type cooling unit for coolant

- High accuracy type with inverter compressor

- High-Accuracy model with the inverter-controlled compressor

- New refrigerant R410A (Modulus of rupture of ozone layer:0)

- Temperature control in low-load range attained by wide cooling capacity control (Conventional: 5~100%→9 series: 0% (no load) to 100%)

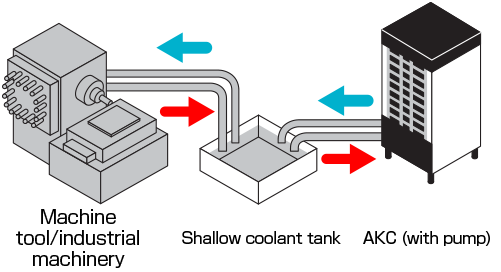

- 1. Setting up to shallow tank is possible

- 2. Easy maintenance

- 3. Extension of cooling capacity control range

- 4. Simple monitoring of operating status

- 5. RoHS-compliant

- 6. Increased tolerance of harsh factory conditions including mist and dust

- 7. Increased tolerance of long-distance transportation

- 8. The smallest size in the class

- 9. The shortest delivery, three-type specifications available in addition to the standard model

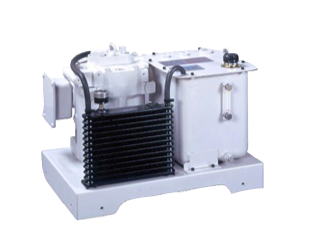

1. Setting up to shallow tank is possible

AKC 9series being an inline type, it be set up to any depth of and existing coolant tank. Built-in pump type is also available.

Setting up to shallow tank is possible(AKC,Built-in pump type)

2. Easy maintenance

The evaporator coil design has been improved to give more durability against clogging. It is also easy to disassemble and clean the evaporator coil.

3. Extension of cooling capacity control range

±0.1°C oil temperature control realized over a load range from 0% (no load) to 100%.

Note: Pattern diagram with the heating load stabilized at 0 - 100%

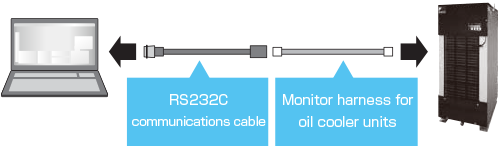

4. Simple monitoring of operating status

Alarm information, operation time, etc., can be monitored from a personal computer

- This is useful for speeding up the identification of parts that need maintenance according to the “Alarm information” readout and shortening machine down times.

- The “Operation time” is a guide to determining the replacement timing for consumables and maintenance intervals.

- *

- Monitoring from a personal computer requires a software tool (Hybrid-Win), the communications cable and the monitor harness.

- *

-

Hybrid-Win is a software tool for monitoring the internal status at a personal computer. Please contact your nearest Daikin distributer to get information of it in details.

- *

- The communications cable and the monitor harness must be purchased separately.

5. RoHS-compliant

Complies with the RoHS Directive, e.g. by adopting printed circuit boards with lead-free solder.

6. Increased tolerance of harsh factory conditions including mist and dust

The ingress protection of the control box has been upgraded (equivalent to IP54).

Sulfur-free parts have been adopted for electronic components.

7. Increased tolerance of long-distance transportation

The specifications for vibration durability during transport have been upgraded to reflect actual transportation conditions.

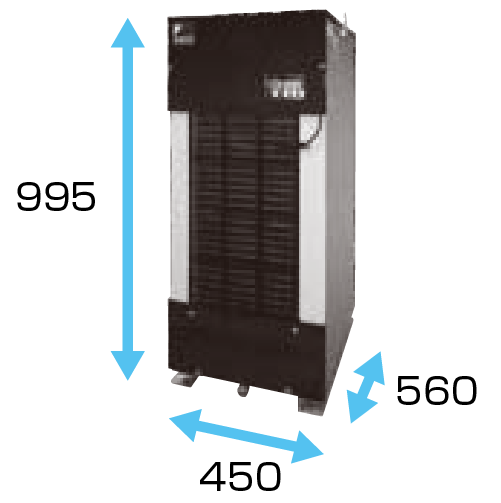

8. The smallest size in the class

(units: mm)

The smallest size in the class

9. The shortest delivery, three-type specifications available in addition to the standard model

CE specifications

-C

Oil heater

-H

Pump

-200

All optional specifications are lised as semi-standard.

Oil cooling unit lineup

AKZ9 SERIES Circulation type

- High-Accuracy, Energy-saving, Compact

Environmentally Friendly Inverter Oil Cooling Unit

AKJ9 SERIES Immersion type

- Immersion-type oil cooling unit mounted directly on the coolant tank

- High-Accuracy model with the inverter-controlled compressor

AKC9 SERIES Circulation type

- Inline type cooling unit for coolant

- Highly accurate temperature control model by inverter control