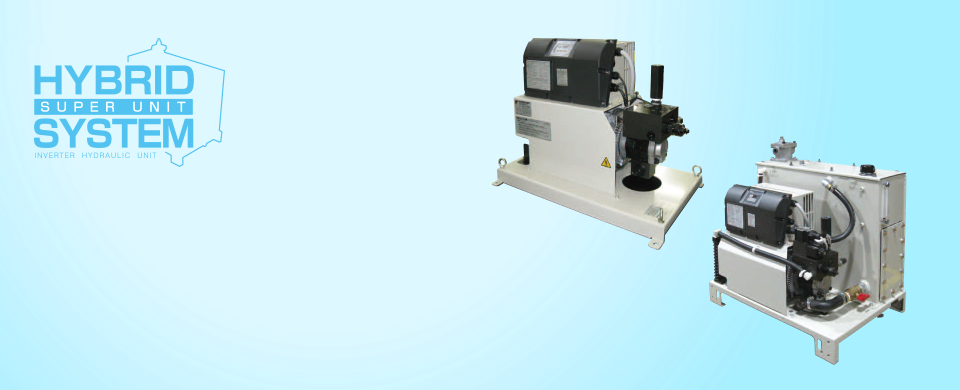

SUPER UNIT

Case studies of energy-saving(Others)

Case studies of energy-saving - Others

| Case of company that measuring instruments | |

|---|---|

| Machine | Machining center |

| Operating hour for one year | 7200Hrs |

| Cost per kWh | 13cents/kWh |

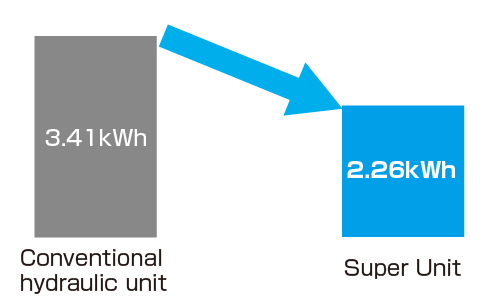

| Cost down by energy-saving effect for one year | 8280kWh |

- ※1

- kWh×0.555(kg):The low of global warming control artcle3.1 in Japan

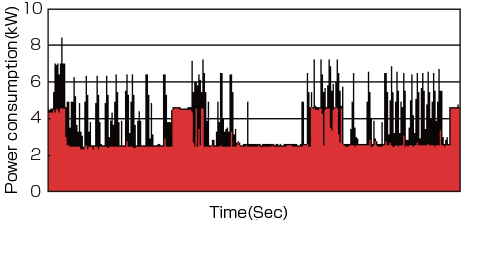

Power consumption of conventional hydraulic unit

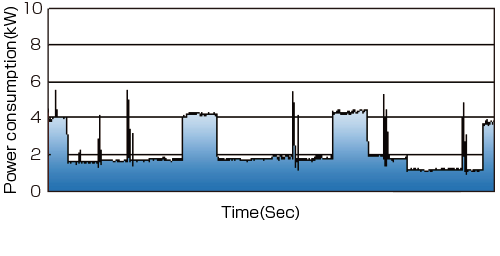

Power consumption of SUPER UNIT

Comparison of power consumption

Power consumpion

(Averge When operating)

about 33.7% reduced

| Model | Pressure | Motor capacity | Tank capacity | ||

|---|---|---|---|---|---|

| Before | Conventional hydraulic unit | Variable piston pump | 7.0MPa | 5.5kW | 140L |

| After | SUPER UNIT | SUT10D6021 | 7.0MPa | Equivalent to 5.0kW | 100L |

- ※1

- This is a case study of energy-saving case in Japan. We assume that operating time is 7200hours for one year and ¥15 per kWh($1=¥107)

- ※2

- kWh×0.555(kg):The low of global warming control artcle 3.1 in Japan