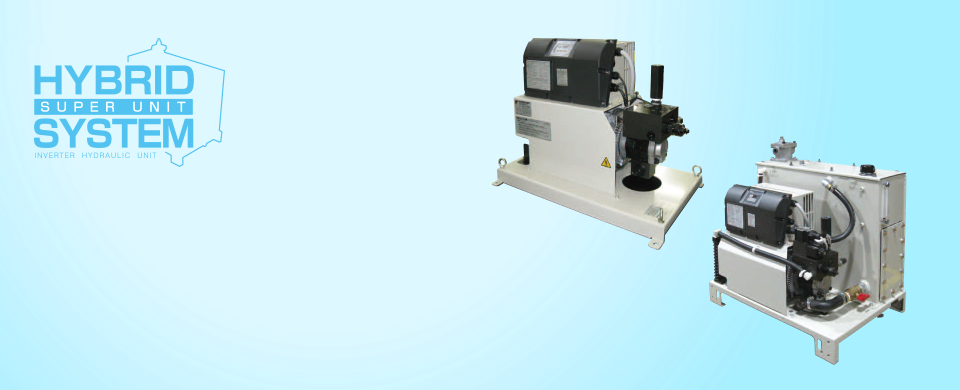

SUPER UNIT Function Options

Function Options of SUPER UNIT are explained.

Communication function (Available as an option with all models)

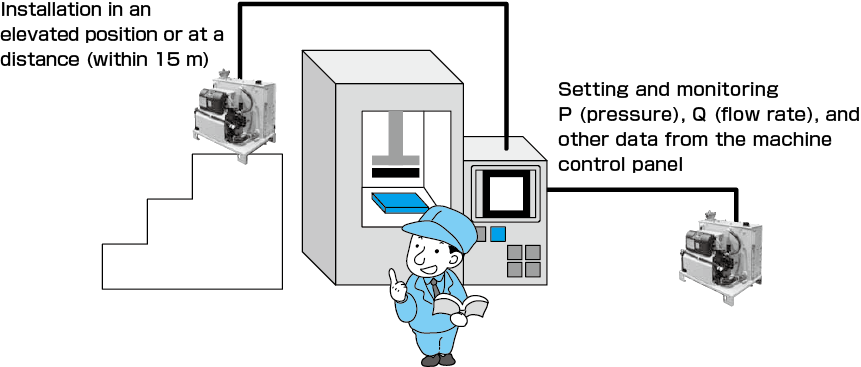

The SUPER UNIT and main machine can be remotely controlled with the same panel. This function eliminates complicated individual operations and installation space limitations.

Remote setting of the operating conditions of the SUPER UNIT enabled

Various settings such as acceleration/deceleration time and pressure switch settings, as well as the pressure and flow rate, can be set remotely. This makes it possible to control the hydraulic pressure operating conditions in synchrony with the control of the machine.

Managing the pressure and flow rate at the machine

The capability to read the operating conditions of the SUPER UNIT makes it possible to display information such as the current pressure and flow rate on the screen at the machine.

- *:

- The serial communication interface conforms to the RS232C standard. (For RS485 interfaces, consult Daikin.) Prepare a control unit such as a PLC or touch panel display with the RS232C communication function at the machine side.

- *:

- For details on the communication procedure, refer to the communication/remove control function instruction manual.

Applications of SUPER UNIT Remote Operation and Communication Functions

Analog command input (Available as an option with single pump type models)

The capability to specify the pressure and flow rate with voltage ranging from 0 to 10 V enables continuous hydraulic control as required. Real-time variation in response to commands facilitates condition settings at the machine side.

- A hydraulic control system for machinery that requires variable speed control or continuity of pressurizing forces can be realized with a simple configuration.

- A joystick or trimmer can be connected for real-time control.