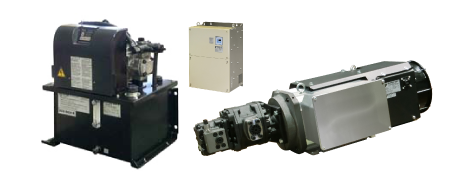

SUPER UNIT

Power pack system with superior performance, which achieved factory energy-saving dramatically. SUPER UNIT, utilizing the Daikin IPM motor has made a great contribution to preservation for global environment.

Features

1. Energy-saving

Energy-savings of 50% (20.6MPa at pressure retained) is realized to give extraordinary cost performance.

(*Compared with a conventional Daikin vasiable piston pump)

- Air-conditioning motor technology and tandem pump selecting control technology are fused to attain high energy saving effects.

- Not only at retained pressure but also in the field of general industrial machinery where actuators are frequently operated, such high-efficiency motors will greatly reduce power consumption and other energy savings.

2. Low heat generation

In view of the energy-saving goal, generation of heat is dramatically suppressed and it can reduce the heat load to the air-conditioning unit.

This reduces the heat load on the air-conditioning unit. Effectiveness by low heat generation.

- Preventing rise of oil temperature and deterioration of operating oil

- Space savings and the reduction oil capacity given that tank size is reduced

- Eliminates the need of an oil cooler

- Suppresses the heat load on the air-conditioning unit

3. Low noise

Low noise 60dB (A) (20.6MPa at retained pressure) is achieved. In all of the operation areas, the noise is 73dB(A) or less.

- The motor is controlled at a lowest optimum speed under retained pressure condition, which achieves the extremely low noise level.

- The phase-differential tandem pump attains low pulsation and low noise (Double-pump specification)

4. Excluded from high-efficiency motor regulations

High-efficiency motor regulations came into effect in Japan in April 2015. These regulations apply to the hydraulic units equipped with general motors but the SUPER UNITs that incorporate a high-efficiency IPM motor are excluded from them.

Advantages of using hybrid hydraulic units

- Eliminates the need for replacement of motors for each destination

- Eliminates the need for design changes in accordance with amendments to the regulations

- Reduces design changes to spare parts, and the maintenance workload

5. All models conforming to CE standards

All models conform to the machinery directive, EMC directive, and low voltage directive. This facilitates CE approval of the main machine.

6. IoT-ready

The IoT-compatible Daikin hybrid systems reduce waste and losses at factory sites.

- With the hybrid system, it is possible to fetch information including not just hydraulic fluid pressures and flow rates but also internal information about the equipment such as power consumption and motor temperatures.

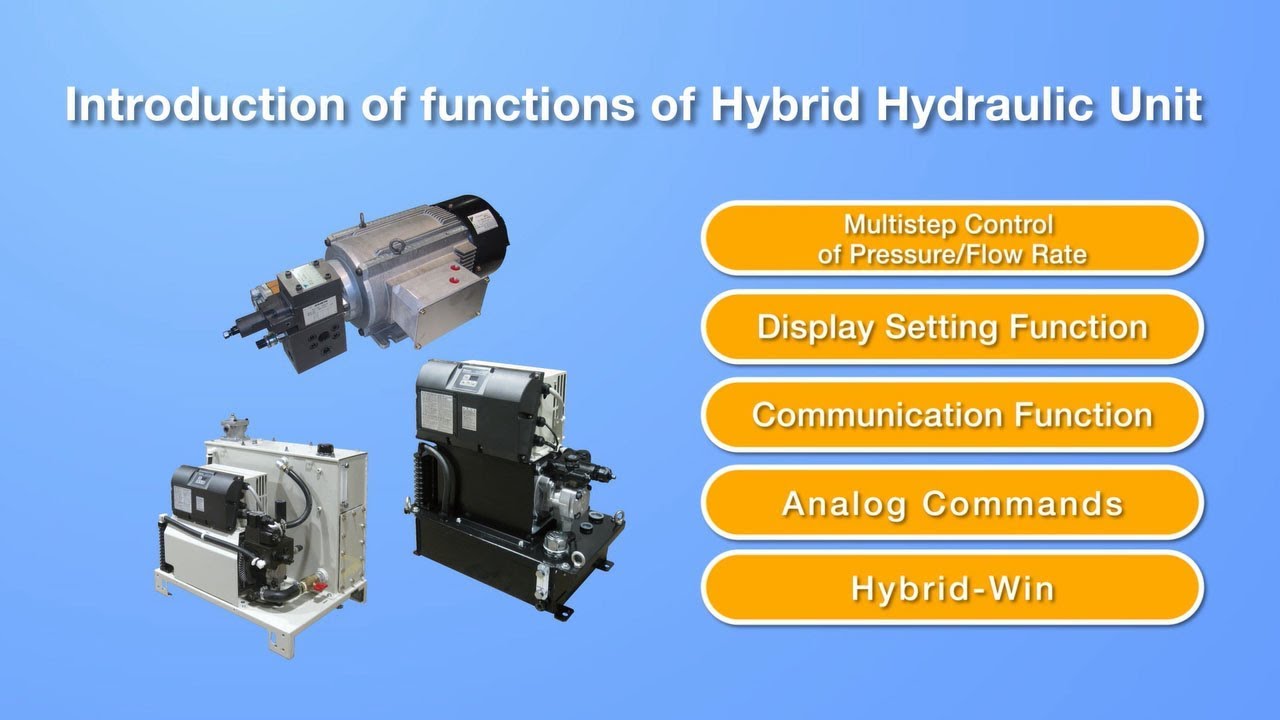

Here we introduce the features of the hybrid hydraulic units in an easy-to-understand manner in a video.

Functions

1. Multi-stage pressure/flow rate control(16 PQ control setting patterns)

Sixteen patterns of pressure (P) - flow rate (Q) setting are available for cylinder control.

- The force (pressure) and speed (flow rate) of the actuator (cylinder) can be controlled with 16 patterns of pressure (P) and flow rate (Q) setting.

- Smooth changing of force (pressure) and speed (flow rate)

2. Maintenance/Management function(Hybrid-Win)

Internal data of the SUPER UNIT can be retrieved to using PC connected to the unit.

- Displaying graphs

- Reading, writing, editing, and saving parameters

- Reading and saving the alarm history

Here we introduce the functions of the hybrid hydraulic units in an easy-to-understand manner in a video.

Function Options

1. Communication function

(Available as an option with all models)

Remote control and setting changes are possible through RS232C serial communication.

- Using a commercially-available PLC or touch panel display with RS232C communication capabilities, parameters for the pressure, flow rate, acceleration time, deceleration time and so on can be set and viewed at the machine. This facilitates control of speeds and pressurizing forces and enables a wide variety of machine operations.

2. Analog command input

(Available as an option with single pump type models)

Enables continuous control of pressures and speeds as required.

- The pressure and flow rate can be controlled continuously at the desired values by inputting the pressure command voltage (0 to 10 V) and flow rate command voltage (0 to 10 V) from the machine side. This achieves a control system with a simple configuration for machinery that requires variable speed control or continuity of pressurizing forces.