Significant reduction of running costs with a small investment. Contributes to improvement of production efficiency at a reasonable price.

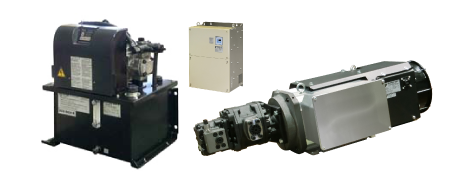

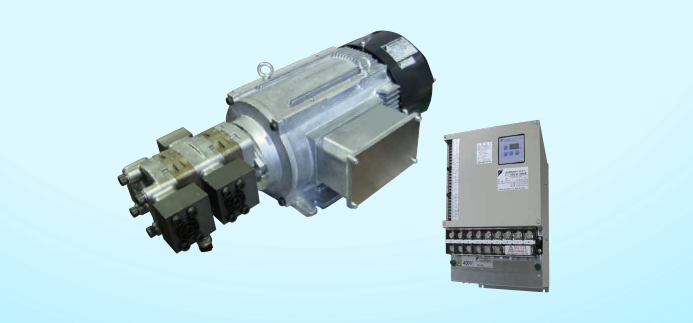

SUPER UNIT

(Analog Command Input, High-Accuracy Type)

Features

Features of SUPER UNIT (Analog Command Input, High-Accuracy Type) are explained.

1. Energy Saving

■Energy savings at least 60% greater than conventional fixed displacement pump systems(The energy-saving effect varies depending on the operation conditions.)

600-t press machine |

|||

|---|---|---|---|

| Pump model | Fixed-displacement pump | → | SUT00D8025 |

| Average power consumption | 21.5kW | → | 13.9kW |

Effect of reduced power consumption: $6,350 (¥635,000) / year |

|||

■Oil cooler downsized by suppressing oil temperature rise

Fewer oil changes by restricting hydraulic oil deterioration. Further, downsizing the hydraulic oil tank and oil cooler reduces the amount of hydraulic oil and cooling water used.

2. High Accuracy with Simple Operation Main Features and Functions Energy Saving 04

■High-Accuracy servo control according to analog pressure (P) / flow rate (Q) voltage commands

Easy to use, just like conventional proportional valves.

The servo-controlled pump adjusts the pressure and flow rate in accordance with the load.

Highly accurate control with respect to pressure/flow rate command values, with a linearity of 1% F.S. maximum and hysteresis of 1% F.S. maximum.

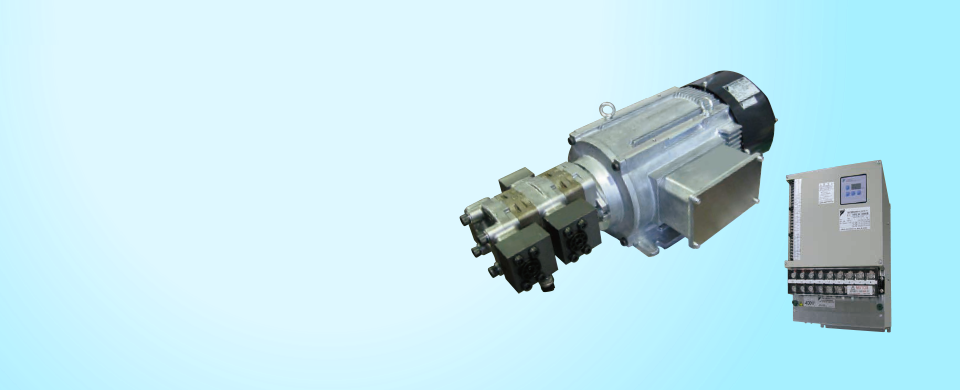

Example with double pump type (SUT00D15021-10-B)

3. Sustained High-pressure Holding Control

■Sustained high-pressure control with energy savings by selecting the pump flow rate

Double pump type units enable selection of combination or independent flow rate using a dedicated solenoid valve to achieve sustained high-pressure control, switching between a low pressure with high flow rate and a high pressure with low flow rate, as is often required for presses and other equipment.

The solenoid valve can be switched autonomously by the SUPER UNIT or from the machine, according to the parameter setting.

4. Faster Shipping Adjustment

■Simple adjustment to start a trial run on the machine, meaning a shorter adjustment time

The SUPER UNIT can be easily adjusted without requiring special skills for setting/adjusting complicated parameters of servo systems. The unit runs stably even with the default settings so the machine can reach the trial run stage in a short time.

■Economical replacement of conventional hydraulic systems with servo-controlled pump systems

Conventional hydraulic systems with proportional valves can be economically replaced with next-generation energy-saving high-accuracy servo-controlled pump systems, where the pump discharge rates and pressures are servo-controlled, by using analog command input type SUPER UNITs.

Even hydraulic systems that do not incorporate proportional valves can be replaced with energy-saving hydraulic systems that can achieve stable control with a simple pressure/flow rate adjustment.

The command input method can be selected, by parameter setting, as the analog command input type (0 to 5 V or 0 to 10 V) or the 8-PQ pattern input type using 3-bit digital ON/OFF input signals. (Factory default is the analog command input type.)

5. Improving the Working Environment

■Reduced noise during operation

Noise while holding a high pressure is reduced by lowering the rotational speed of the pump to the minimum level required to hold the pressure.

Shockless control of pressures and flow rates can be achieved by ramping the command voltages during acceleration/deceleration of the pressure and flow rate. This gives smooth machine operation with less impact noise, helping to improve your working environment.

■Ambient air temperature rise reduced by restricting oil temperature rise

Temperature rise of the hydraulic oil raises the ambient temperature, which leads to a poor working environment. The energy-saving SUPER UNIT restricts hydraulic oil temperature rise to the minimum, helping to maintain a comfortable working environment.

6. Exceeds Standard of High Efficiency Motor regulation

■Incorporating a motor dedicated to servo-based rotational speed control

Exceeds standard of high efficiency motor regulations eliminates complicated formalities both in Japan and when exporting the machine.

Since no induction motor is used, the maximum discharge rate of the pump does not fluctuate depending on the power supply frequency, making it unnecessary to adjust the machines’ maximum speed for each shipping destination.