Energy saving

Problem: Considerable measurements have already taken for energy-saving at the plant, but still need to look for new opportunities to achieve energy-saving target.

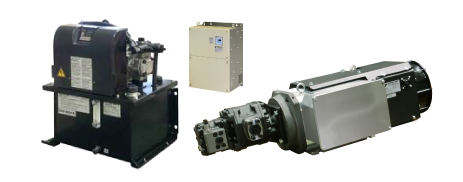

Solution: Daikin’s inverter hydraulic units contribute to greater plant energy-saving. On a standard production line, about 45% of all power consumption comes from the processing portion of the operation. Most of the fixed consumption consists of the hydraulic unit, oil cooling and coolant pump, so it is imperative to start energy saving in such hydraulic equipment.

Daikin’s unique oil hydraulic system has incorporated a highly efficient IPM motor, which is the key technology to energy-saving in air conditioners with over millions installations. This IPM motor has all the features that are needed for oil hydraulics, such as high-efficiency, high-response, and high-speed rotation. By controlling the rotation speed of the IPM motor with an inverter, the power consumption can be reduced greatly. More than 50 % of energy-saving is realized by reduction of the motor rotating speed under retained pressure condition.

Low noise

Problem: Noise reduction is required to improve the working environment in the plant.

Solution: The motor from Daikin’s hydraulic unit is controlled at a lowest optimum speed under retained pressure condition, which achieves the extremely low noise level. For instance, the noise level of SUPER UNIT during retaining pressure is about 60db, which is almost the same as the volume of a daily conversation. Noise in plants is totally harmful to worker’s health, and low noise contributes greatly to a better working environment.

Communication function

Problem: Maintenance is quite time-consuming to achieve stable operation of production lines.

Solution: Communication function of Daikin’s inverter hydraulic units eliminates the need for routine maintenance. The process like periodic inspections is generally recommended to hydraulic units, but such work is a major burden on the site. Also, the breakdown of hydraulic equipment can lead to long-term shutdown of the production line. With Daikin’s hydraulic system, an operation status can be monitored all the time, so there is no need for periodic inspections, and it gets much easier to predict system failure. Maintenance can be performed at truly appropriate times to ensure stable operations.

User-friendly

Problem: Lack of knowledge to design complex hydraulic circuits

Solution: With Daikin’s inverter hydraulic units, complex circuits can be realized with simple control. These units come standard with multi-stage pressure and flow control function. Once the pressure and flow rate has been set at the controller’s operation panel, Daikin inverter hydraulic units autonomously change the control mode from flow rate control to pressure control. Remote setting from the main machine is also possible by the communication function. Pressure control valves and proportional flow control valves, which are utilized in conventional circuits, are not required. The force and speed of the actuator can be controlled with 16 pressure (P) and flow rate (Q) setting patterns (high-performance types of SUPER UNIT), so optimal control is possible.

Compact and lightweight

Problem: Want to place many machines in the factory to improve the productivity, but there is not enough space

Solution: Compared to conventional hydraulic units, Daikin’s inverter hydraulic units are smaller and lighter. Downsizing of machines has been well received as it leads to cost reductions, and it has simplified the machine design.

Low heat generation

Problem: Having many troubles with hydraulic system, such as oil leaks

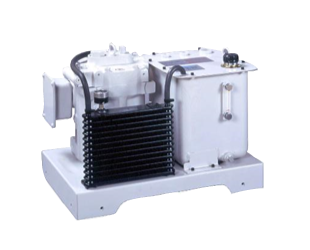

Solution: Daikin’s inverter hydraulic units dramatically suppress generation of heat. Heat generation is troubling for hydraulic systems as this not only increases the possibility of breakdown of the main machine, but also the rise of oil temperature leads to the various troubles in hydraulic equipment. Suppression of oil temperature prevents deterioration of operation oil and oil seal, which in turn avoids oil leaks. Running costs can also be reduced by preventing deterioration. Inverter controlled water chillers, which realize heat-less, are also highly valued to make factory operations more comfortable.

Excluded from high-efficiency motor regulations

Problem: Checking country-specific regulations when exporting machines is troublesome

Solution: High-efficiency motor regulations generally apply to hydraulic equipment with conventional motors, but SUPER UNITs and ECORICH that incorporate IPM motor are excluded from regulations. There is no need for reselect or redesign motors for each country of export.

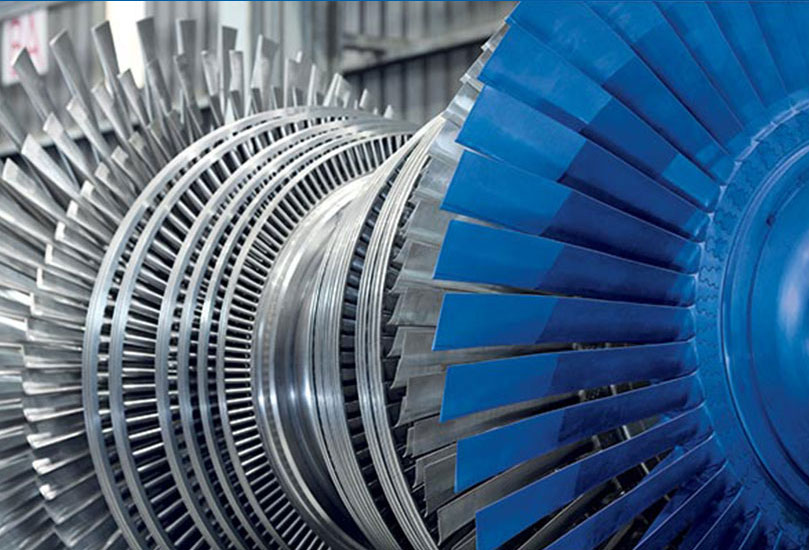

Improved machining accuracy

Problem: Productivity has not improved as machining accuracy is unstable

Solution: Daikin’s hydraulic system contribute greatly to the consistency of machining accuracy. The controller and the monitor control each other’s pressure and flow rate, so high reproducibility is realized. The low heat generation also suppresses the effect on oil viscosity, which has a significant impact on machining accuracy.

Also, with Daikin’s fluid cooling units, high-Accuracy temperature control (±0.1°C) is achieved by fusing hydraulic technology and inverter technology. The thermal displacement can be eliminated, and this function is helpful to improve machine accuracy.