Energy-saving technology of Daikin

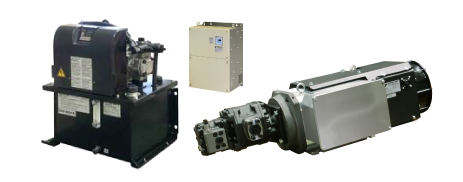

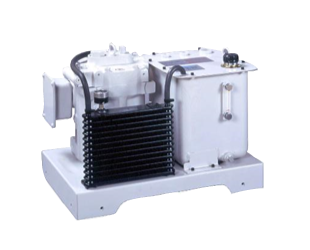

Fusion of oil hydraulics and motor/inverter technology

Energy-savings of more than 50% (In comparison of a conventional hydraulic system to our product while when pressure is retained).

The dramatic energy-savings is realized by reduction of the motor rotating speed under retained pressure condition.

The high-efficiency IPM motor will achieve energy-savings even in the general industrial machine field where the operation ratio of actuators is high.

Principle of energy-saving in terms of operating pattern (Case of Daikin SUPER UNIT).

The power consumption is dramatically reduced under retained pressure condition because of the variable speed operation of our motor.

Differences between hybrid system and conventional system

Energy-saving

- ✖

- Constant motor rotating speed at all time

- ◎

- Motor rotating speed is developed as required

Noise

- ✖

- Very noisy

- ◎

- Quiet while retained pressure

Tank size

- ✖

- Large (required for cooling of fluid)

- ◎

- Small (low heat generation means less required capacity)

Machine configuration

- △

- Complicated (piston pump)

- 〇

- Simple (gear pump)

Cost

- 〇

- Low(on the parts of software)

- △

- High(Inverter is expensive)

- 〇

- Elimination of valves by use of software & control reduces cost.

Engineering

- △

- Simple however there are few people with oil hydraulic skills and experience.

- 〇

- Technical skills are required. An example is knowledge of how to set software parameters is required though the setting procedure is straightforward.