The following can be achieved by installing the option communication board on the oil cooling unit’s control board and communicating with the machine:

1. Changing the operation mode and the operation setting from the machine

2. Reading various data such as the alarm code and temperature-related data of the oil cooling unit from the machine

On the 10 series, a new function for quantifying and communicating the margin level before occurrence of an alarm has been added. The machine can now receive that value and use it to judge the maintenance timing or for other purposes.

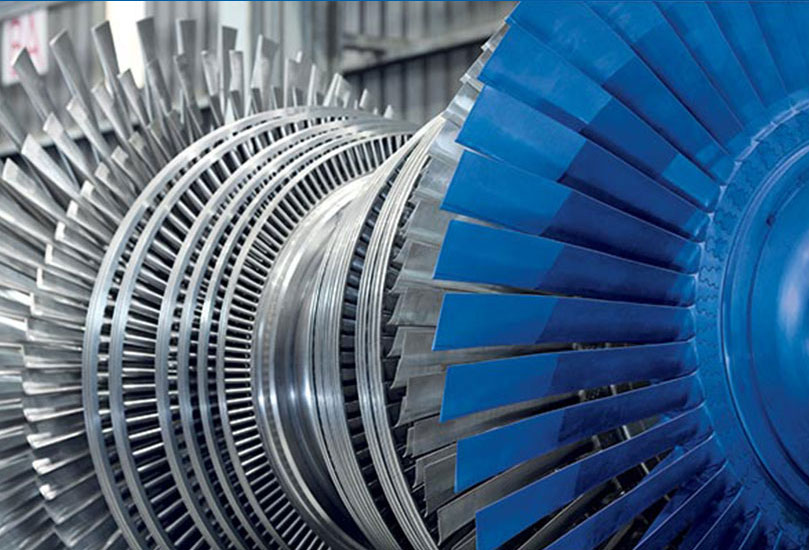

Extreme energy saving with original compressors and inverters

High-accuracy temperature control over the full performance range (±0.1℃)

Room temperature 5 to 45℃, fluid temperature 5 to 50℃

- Measures against dust and oil mist (electrical enclosure rating IP54)

- robust during transport, substrate sulfide resistant specifications

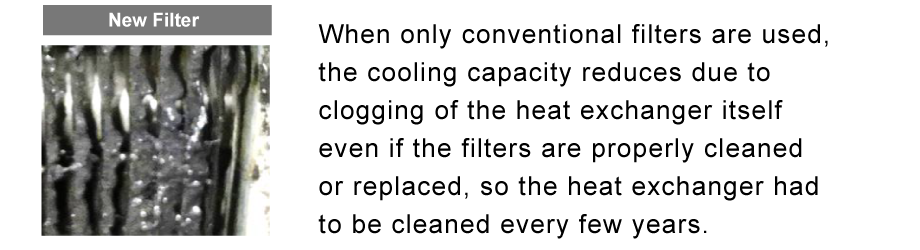

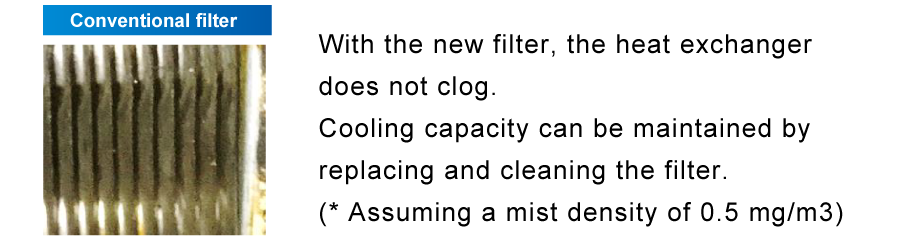

- wide fin pitch making the heat exchanger resistant to clogging

- Refrigerant gas leakage detection

- temperature warning, auto-tuning function

- ON timer

- predictive maintenance function

(maintenance timing announcement, stop-gap operation in the event of a thermistor fault)

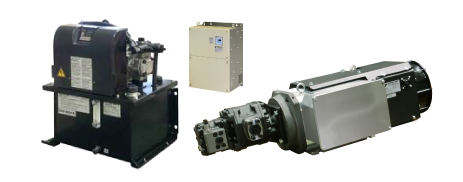

Oil cooling unit lineup

AKZ9 SERIES Circulation type

- High-Accuracy, Energy-saving, Compact

Environmentally Friendly Inverter Oil Cooling Unit

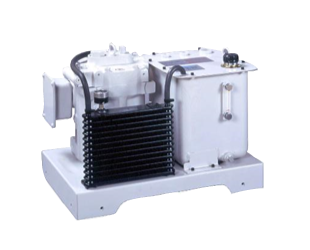

AKJ9 SERIES Immersion type

- Immersion-type oil cooling unit mounted directly on the coolant tank

- High-Accuracy model with the inverter-controlled compressor

AKC9 SERIES Circulation type

- Inline type cooling unit for coolant

- Highly accurate temperature control model by inverter control